Oil-resistant hose how to improve oil resistance.

The oil resistance of the oil-resistant hose mainly depends on its material and manufacturing process. The following are some suggestions to improve the oil resistance of oil resistant hoses:

1. Use a rubber material with high oil resistance. For example, reclaimed rubber containing groups has good oil resistance, such as nitrile reclaimed rubber. At the same time, high oil-resistant rubber products are recommended to use nitrile reclaimed rubber or nitrile reclaimed rubber, chloroprene reclaimed rubber and use, to further improve the comprehensive performance of oil-resistant rubber products.

2. Add oil resistant plasticizer. Oil-resistant plasticizer can reduce the force between rubber molecules, improve the plasticity and fluidity of the rubber compound, so that the rubber compound is easier to process. At the same time, some oil-resistant plasticizers can also improve the oil resistance of rubber. For example, ester compounds, etherification and nitrile rubber material are similar, can be good compatibility with nitrile rubber, is commonly used in the production of nitrile rubber products plasticizer. It should be noted that different plasticizers have different degrees of influence on oil resistance, and suitable plasticizers need to be selected according to actual needs.

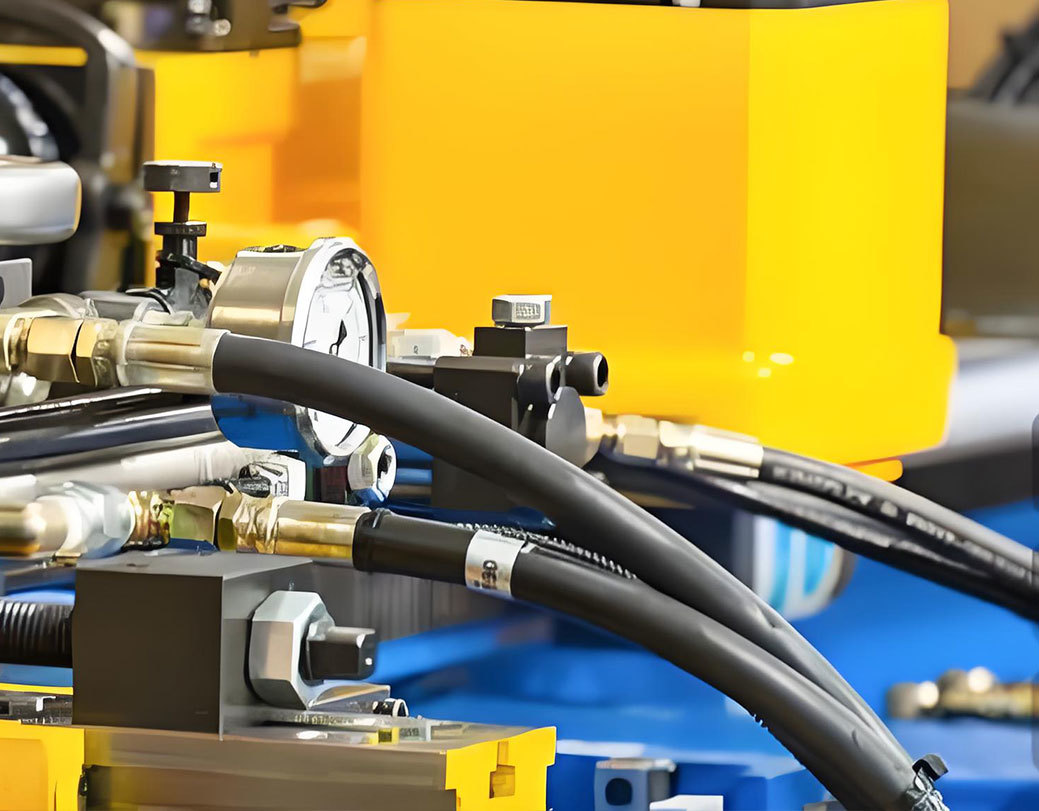

3. Adopt advanced manufacturing process. The manufacturing process of oil-resistant hose also has a great influence on its oil resistance. For example, in the process of extrusion and vulcanization, process conditions such as high temperature, high pressure and high speed can be used to improve the compactness and sealing performance of the hose, thereby enhancing its oil resistance.

4. Add enhancers. Adding enhancers can enhance the physical properties and oil resistance of the hose. For example, the addition of glass fiber can improve the strength and heat resistance of the hose: the addition of carbon black can improve the oil resistance and conductivity of the hose.

Previous:

The next one:

Recommend News

Congratulations on the official launch of the website

Hengshui yatai rubber products co., ltd (Hengshui yatai Especial rubber Products co., ltd.) was founded in 2001 and is a professional manufacturer of high-performance rubber hoses.

Performance and Application of High Temperature Steam Hose

In modern industrial production, high temperature steam hose is a very important equipment and has a wide range of applications. It can not only transport high-temperature steam, but also withstand high pressure and wear resistance, so it has been widely used in many industrial sites.